Huawei Named Most Innovative Enterprise in Powertrain Technology

[Shanghai, June 17, 2021] Huawei DriveONE took home the award for the Most Innovative Enterprise in Powertrain Technology for its DriveONE ePowertrain. The award was presented at the Global xEV Powertrain Technology & Industry Conference 2021. DriveONE — industry's first high-voltage all-in-one ePowertrain system — features innovative solutions in high-voltage four-wheel drive, intelligent oil cooling, and electro-erosion prevention. The selection process was conducted through multiple rounds of revision by a panel of experts on electric vehicles (EVs).

Huawei Receives Award for DriveONE ePowertrain

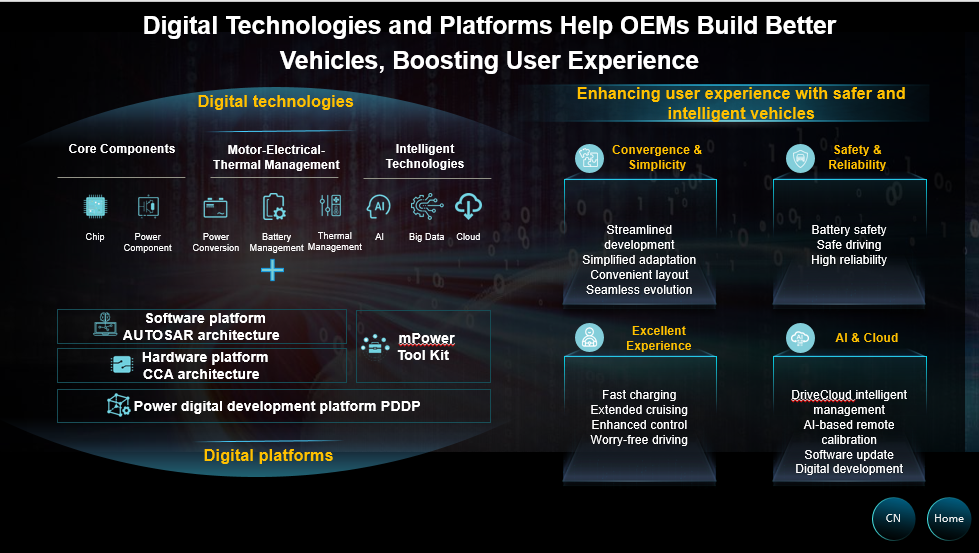

1.Digital Technologies and Platforms Help Automakers Build Better Cars and Improve User Experience

Huawei mPower is rooted in digital power technologies, featuring self-developed chips, motor-electricity-thermal management, and computing with AI, big data, and cloud. We have three digital platforms for hardware, software, and digital development. All this helps automakers quickly design and iterate car models, building better cars. Huawei mPower specifically focuses on automaker requirements and user experience. Based on these, we build innovative power domain solutions that feature high convergence, simplicity, safety and reliability, excellent experience, and cloud-based AI.

Digital Technologies and Platforms Help Automakers Build Better Cars and Improve User Experience

2.Unique High-Voltage Four-Wheel Drive ePowertrain Optimizes Energy Efficiency

Huawei's unique high-voltage four-wheel drive solution with 220 kW front asynchronous and 270 kW rear synchronous motors provides optimal power and fast charging. With the 800 V high-voltage architecture, a car can be charged from 30% to 80% SOC in 15 minutes — the time it takes to grab a cup of coffee. Cars can also accelerate from 0 to 100 km/h in 3.5 seconds, a similar range to supercars. Compared with the dual synchronous solution, Huawei's high-voltage four-wheel drive solution delivers 3.5% higher NEDC efficiency and 5% longer battery life.

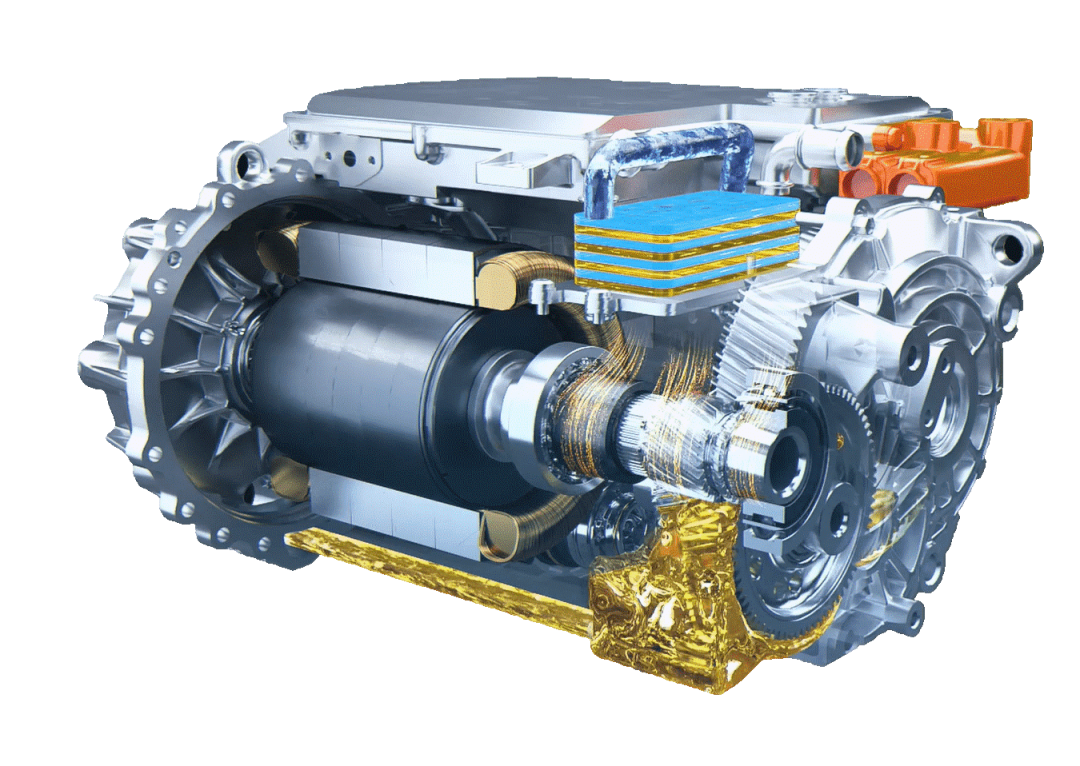

DriveONE 3-in-1 ePowertrain

3.Intelligent Oil Cooling Technology Is Super Compact, Delivering Long Service Life and Excellent Performance

Thanks to oil-cooled technology, Huawei's motors are 15% smaller than water-cooled ones, under the same power and torque. The rotor and stator of the motor are immersed in oil. The average peak winding and magnetic steel temperatures drop by 30°C and 15°C, respectively, doubling the service life. Based on the thermal simulation results, the unique oil channel design with active spray is used for components that tend to heat up. Bearings and gears are actively lubricated, extending the bearing life by 10%. Cooling performance also increases in the high-speed zone. The maximum rotational speed goes up to 18,000 rpm, allowing the car to run faster and accelerate from 0 to 100 km/h twenty times in a row.

Intelligent Oil Cooling

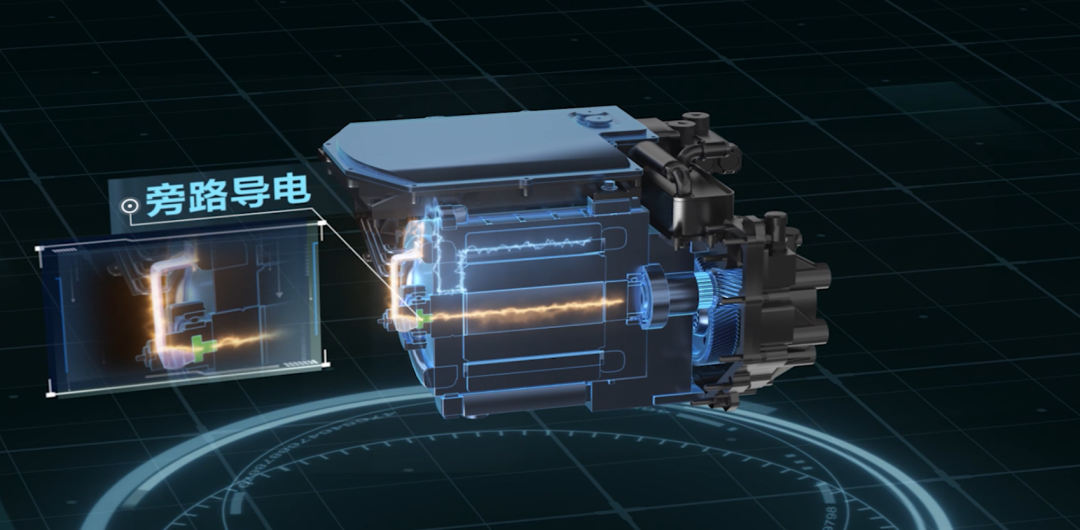

4.Huawei-patented Franklin Flow Diversion Solution Reduces the Risk of Electro-erosion of Bearings

Huawei DriveONE ePowertrain uses the patented Franklin flow diversion solution that adds additional bypass conductive loops to release shaft voltage and current. This reduces the risk of oil film breakdown between bearings and their electro-erosion. In addition, the conductive grease with Huawei-patented ratio features excellent conductivity and compatibility. It is temperature- and pressure-resistant, further preventing the electro-erosion of bearings.

Huawei-patented Franklin Flow Diversion Solution

5.AI Improves Quality and Lifespan of ePowertrain

Huawei mPower has established a complete AI pyramid model for the entire lifecycle of the DriveONE 3-in-1 ePowertrain. Design, manufacturing, testing, and running are all optimized, assuring quality and extending the lifespan.

Design

Multiphysics coupled AI simulation optimization speeds up development, improving its efficiency by 10%.

Testing

The failure root cause analysis model and abnormal sample outlier algorithm intelligently filter incoming materials and finished products to reduce the PPM.

Running

Mechanism + AI coupling iteration enables fault warning and predictive maintenance of the ePowertrain, and improves the quality of the design and testing processes.