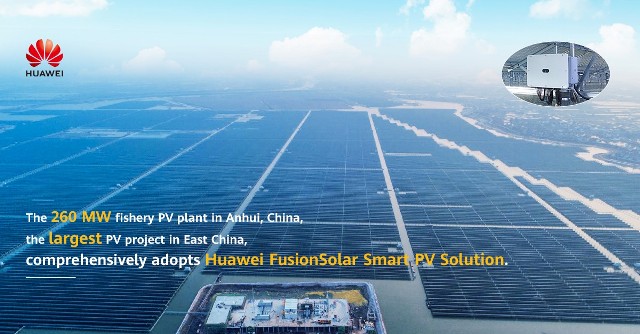

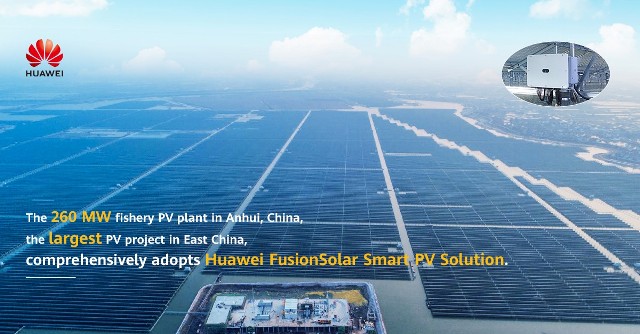

In late 2019, the 260 MW fishery PV plant was successfully grid-tied in Dangtu County, Ma'anshan City, Anhui Province. Currently, China General Nuclear Power Corporation (CGN) has achieved breakthroughs in the operating installed capacity, attaining over 20 million kW. This marks a new phase in the company's high-quality and large-scale development.

The CGN Dangtu project was one of the first grid-parity PV projects approved by the National Development and Reform Commission (NDRC) in 2019. Furthermore, among the first batch of PV demonstration projects in Anhui, it is the only that has been fully implemented, making it the largest in East China. Covering approximately 4,000,000 m2 of waters, the project comprehensively adopts the Huawei FusionSolar Smart PV Solution, with on-grid tariffs amounting to approximately 5.4 cents per kWh and capacity equaling 260 MWp. In addition, the integration of fishery and power generation maximizes profits.

Fishery PV plants face the following construction and maintenance challenges:

- It is difficult to pile and route cables for water-based operations.

- High temperature and humidity aggravate the potential induced degradation (PID) effect.

- In vast waters, O&M is time-consuming and costly.

- In terms of eco-friendliness, there are high requirements for fishery-solar integrations.

To overcome these challenges, the project adopts the Huawei Smart PV Solution, which integrates cutting-edge intelligent technologies, such as Smart I-V Curve Diagnosis, MBUS communication, and patented PID prevention. This solution is highly beneficial in terms of high energy yields, high reliability, and low O&M costs.

Five Technologies: The Fishery PV Plant's Foundation

1. Multiple MPPTs Ensure High Energy Yields

The project utilizes Huawei SUN2000 smart inverters, configuring each megawatt with 80 maximum power point trackers (MPPTs). This minimizes the impact of PV module mismatch caused by shading, inappropriate direction, and other factors, and improves the system efficiency, ensuring high energy yields. Currently, the fishery PV plant's energy yield has increased by more than 3%.

2. MBUS Communication Ensures Reliable Transmission

Water-based operations, which pose high technical requirements and are difficult to implement, must be established during the construction of fishery PV plants. When you take into account the large scale of this project (88,866 pipe piles), it becomes apparent that the traditional communication solution cannot meet requirements due to extended construction periods and poor transmission reliability.

To overcome these challenges, Huawei has applied the all-new MBUS broadband power line communication technology, reducing the investment and O&M costs of RS485 cabling. Signals can now be directly transmitted over power lines, with a higher transmission rate of 115 kbit/s, stronger interference immunity, and higher transmission reliability.

3. Patented Anti-PID Technology Ensures Safety During Power Generation

Damp environments with high temperatures have severe PID effects. This is because that water vapor usually collects on water surfaces, eroding PV modules and causing energy yield losses. To mitigate this effect, Huawei's latest PID suppression technology utilizes proprietary technologies to build a virtual neutral point through solar inverter circuits. Compared with traditional solutions that use resistors or inductors to build the neutral point, Huawei's PID suppression technology represents a major upgrade as it reduces compensation losses and ensures safety throughout the process. As a result, energy yield increases by more than 2% while supporting a larger array of more than 5 MW.

4. Smart I-V Curve Diagnosis Ensures O&M Efficiency

Traditional PV plant inspections are time-consuming and inefficient. In addition, errors are bound to occur during manual sampling, especially for water-based inspections. The AI-powered Smart I-V Curve Diagnosis can remotely detect all PV modules in the entire PV plant. It is certified by TÜV that 14 types of PV module faults can be accurately identified with reports automatically generated. For a 100 MW PV plant, PV string faults can be scanned within 15 minutes, eliminating the need for site visits and boosting O&M efficiency. Evidently, this technology is capable of solving pain points in complex scenarios, such as fishery application.

5. Integrated Convergence for Ecosystem Friendliness

To ensure water quality and protect aquatic animals, monitoring sensors and controllers need to be connected to PV plants. These devices can be connected to the nearest smart PV transmission channel to save cable and labor costs, and ensure data transmission stability and device control. In addition, with AI Boost Suite and Smart I-V Curve Diagnosis, which integrate fishery and PV management modules, the management process has become significantly more simple and efficient.

As the largest grid-parity PV project in East China, CGN Dangtu PV plant serves as a model for integrating smart PV and fishery. CGN is committed to ensuring this project becomes a benchmark for ecological PV plants in China, and promoting the comprehensive development of ecological fishery, to create a world that is eco-friendly.

India

India